News

Broadwell Air Dome

Site

/uploads/image/677267645dfcf.png

China's first air dome workshop for deep processing of shield tunneling slurry was successfully built in Shaanxi, using innovative air-supported structure technology. The project was completed in just 20 days, overcoming challenges related to cultural heritage protection and airport height restrictions. Featuring eco-friendly, intelligent, and resource-recycling solutions, it sets a benchmark for green industrial transformation and sustainable development.

Site

/uploads/image/677267645dfcf.png

China's first air dome workshop for deep processing of shield tunneling slurry was successfully built in Shaanxi, using innovative air-supported structure technology. The project was completed in just 20 days, overcoming challenges related to cultural heritage protection and airport height restrictions. Featuring eco-friendly, intelligent, and resource-recycling solutions, it sets a benchmark for green industrial transformation and sustainable development.

China's First Air Dome Workshop for Deep Processing of Shield Tunneling Slurry Launched in Shaanxi

Views: 1361

Author: Broadwell Air Dome

Publish Time: 2025-08-12

Origin: Site

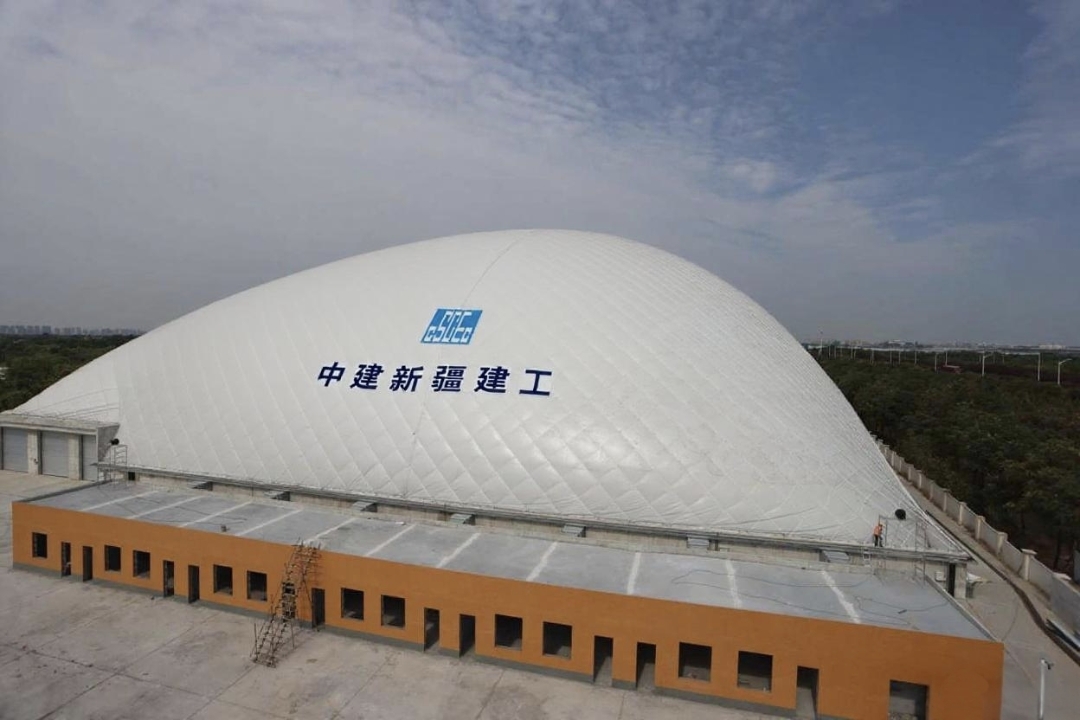

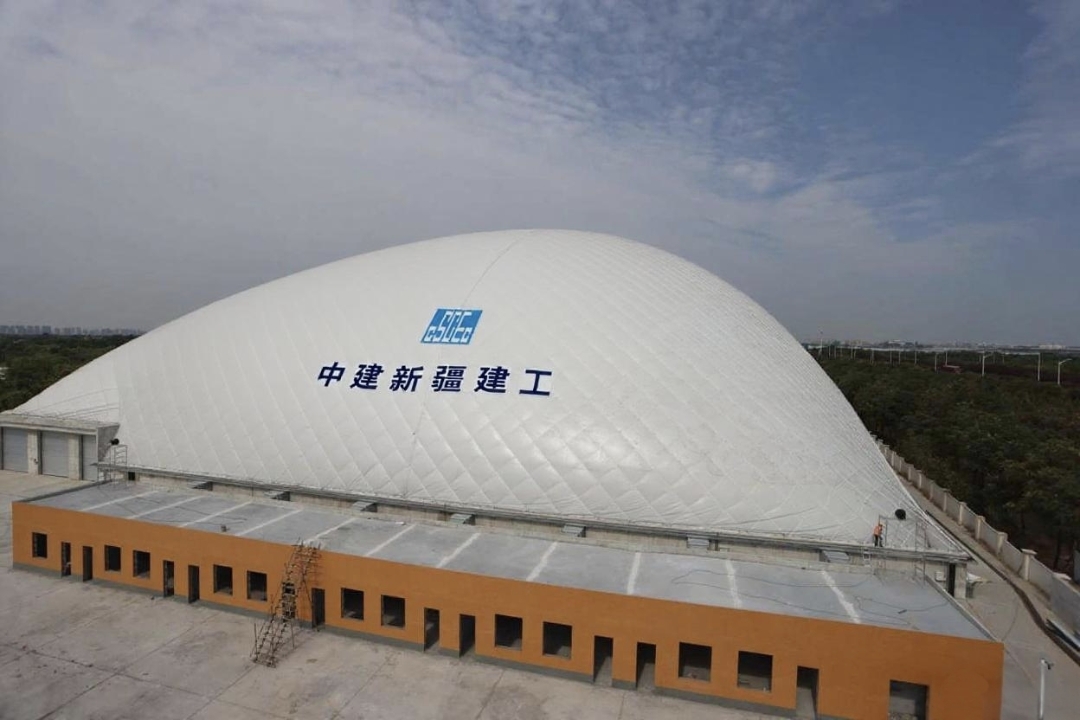

Recently, the Shaanxi Ningyuan Air Dome Workshop for the deep processing of shield tunneling slurry, constructed by Broadwell Air Dome, successfully completed the inflation of a 50,000-square-meter air dome structure! As the first air dome building in China’s shield tunneling slurry sector, this project addresses the dual challenges of cultural heritage protection and airport height restrictions through innovative design, eco-friendly technology, and efficient construction, setting a benchmark for the green transformation of industrial buildings.

Project Background: Overcoming Dual Challenges

The project is located in the Qinhang New City of Xixian New Area, characterized by unique site conditions:

-

Cultural Heritage Protection Zone: Situated within a key protection area, excavation is strictly prohibited.

-

Strict Airport Height Regulations: Located just 3 km from Xi'an Xianyang International Airport, the project must comply with stringent height clearance requirements.

Faced with the challenges of traditional steel structure factories, which are often costly, time-consuming, and environmentally unfriendly, Broadwell has introduced an innovative, fully enclosed air-supported dome structure. This solution offers four key advantages: lightweight design, controllable height, near-zero pollution, and fully enclosed operation, achieving a balance between industrial construction and ecological preservation.

Technical Highlights: Broadwell Air Dome's Green Intelligence

1. Modular and Efficient Construction, Completed in Just 20 Days

The project utilizes factory-prefabricated membrane materials and diagonal mesh steel cables, with on-site assembly combined with overall inflation technology. Small electric tools facilitate quick connections, minimizing reliance on high-altitude work and heavy machinery. The entire process, from material arrival to completion, takes only 20 days, resulting in a massive air dome factory measuring 434.3 m X 115.3 m.

2. Environmental Protection Throughout the Lifecycle

Recyclable Materials: The project employs PVDF flame-retardant membrane materials and galvanized steel cables, which can be 100% recycled at the end of their lifecycle or during relocation, significantly reducing construction waste.

Zero Pollution During Construction: The construction process requires no water, concrete pouring, or complex welding, resulting in minimal noise and waste emissions, thereby reducing disruption to the surrounding environment.

Ultra-Energy Efficient Operation: The PVDF membrane’s light transmission meets over 80% of daytime lighting needs, and its excellent airtightness and insulation can achieve energy savings of over 75% compared to traditional buildings.

3. Intelligent System Integration, Creating a Unmanned Workshop

Utilizing a 5G IoT smart control system, the workshop integrates nine subsystems (main dome system, Bias-Pro Diagonal Orthogonal Steel Cable Hardness System and foundation anchoring system, fire protection system, electrical system, lighting system, sensing and monitoring system, fresh air exchange and dust removal system, smoke exhaust system, and safety monitoring system). This setup enables real-time monitoring of internal and external pressure, temperature, humidity, and harmful gas levels, facilitating smart alerts, remote operation, and low-carbon functionality.

Social Value: A New Benchmark for Resource Recycling and Ecological Protection

Transforming Shield Tunneling Slurry into Resources: The enclosed air dome workshop efficiently processes metro and tunnel shield slurry, converting it into recycled engineering materials through separation technology, thereby addressing soil pollution and land waste issues.

Dust and Noise Mitigation: The fully enclosed design significantly reduces dust dispersion, minimizing the impact on the surrounding environment.

Industry Demonstration: This project provides replicable solutions for industrial construction in cultural heritage protection areas and height-restricted zones.

As a global leader in air dome technology, Broadwell, in collaboration with China Construction Xinjiang Construction and Shaanxi Ningyuan New Material, integrates green air dome construction concepts, intelligent technology, and industry applications to tackle key technical challenges in development. This partnership helps clients build core competitiveness in green and digital construction, paving the way for high-quality sustainable development.