News

Broadwell Air Dome

Site

/uploads/image/677267645dfcf.png

Middle Eastern air domes operate under extreme ground temperatures near 60°C, which severely weaken PVC membranes (strength loss up to 75%) and make welded seams brittle—the structure’s most crack-prone points. A diagonal orthogonal steel cable net system is therefore essential. Acting as a heat-insensitive “skeleton,” the mesh redistributes wind and sandstorm loads from the membrane to steel cables and transfers forces directly to the foundation. It also limits oscillation and strain, protecting vulnerable seams. Unlike simple longitudinal/transverse or basic cross layouts, the diagonal orthogonal pattern provides continuous, omnidirectional load paths and eliminates corner blind spots. In high-temperature regions, this cable system is not a premium add-on but a technical necessity, delivering engineered redundancy, fail-safe safety, and reduced risk for owners.

Site

/uploads/image/677267645dfcf.png

Middle Eastern air domes operate under extreme ground temperatures near 60°C, which severely weaken PVC membranes (strength loss up to 75%) and make welded seams brittle—the structure’s most crack-prone points. A diagonal orthogonal steel cable net system is therefore essential. Acting as a heat-insensitive “skeleton,” the mesh redistributes wind and sandstorm loads from the membrane to steel cables and transfers forces directly to the foundation. It also limits oscillation and strain, protecting vulnerable seams. Unlike simple longitudinal/transverse or basic cross layouts, the diagonal orthogonal pattern provides continuous, omnidirectional load paths and eliminates corner blind spots. In high-temperature regions, this cable system is not a premium add-on but a technical necessity, delivering engineered redundancy, fail-safe safety, and reduced risk for owners.

Air Dome 101 | Why Do Air Domes in the Middle East Need Diagonal Orthogonal Steel Cable Net Systems?

Views: 613

Author: Broadwell Air Dome

Publish Time: 2025-12-02

Origin: Site

Across the Middle East, modern air domes are rising, offering comfortable environments—warm in winter, cool in summer—for sports and recreation. But behind this vision lies a serious challenge: extreme heat.

If you know air domes, you know they’re supported by internal air pressure. What’s less known is that in the Middle East, the key difference between a reliable dome and a risky one often hinges on whether it’s equipped with a diagonal orthogonal steel cable net system. In high temperatures, this system is the air dome’s lifeline.

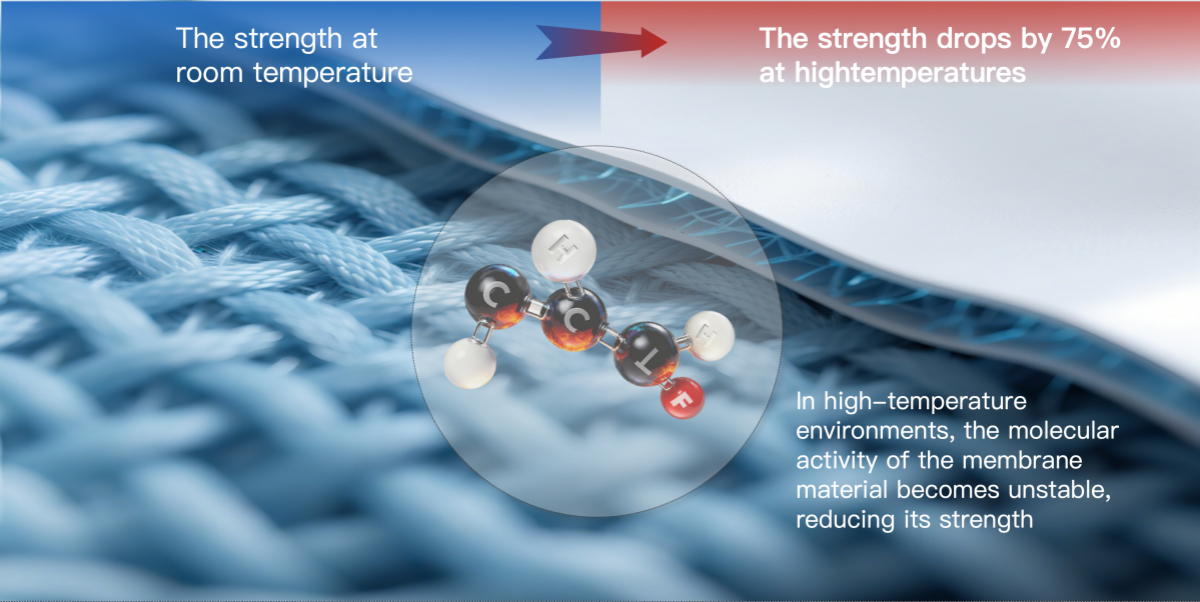

How Does Extreme Heat Affect an Air Dome’s Strength?

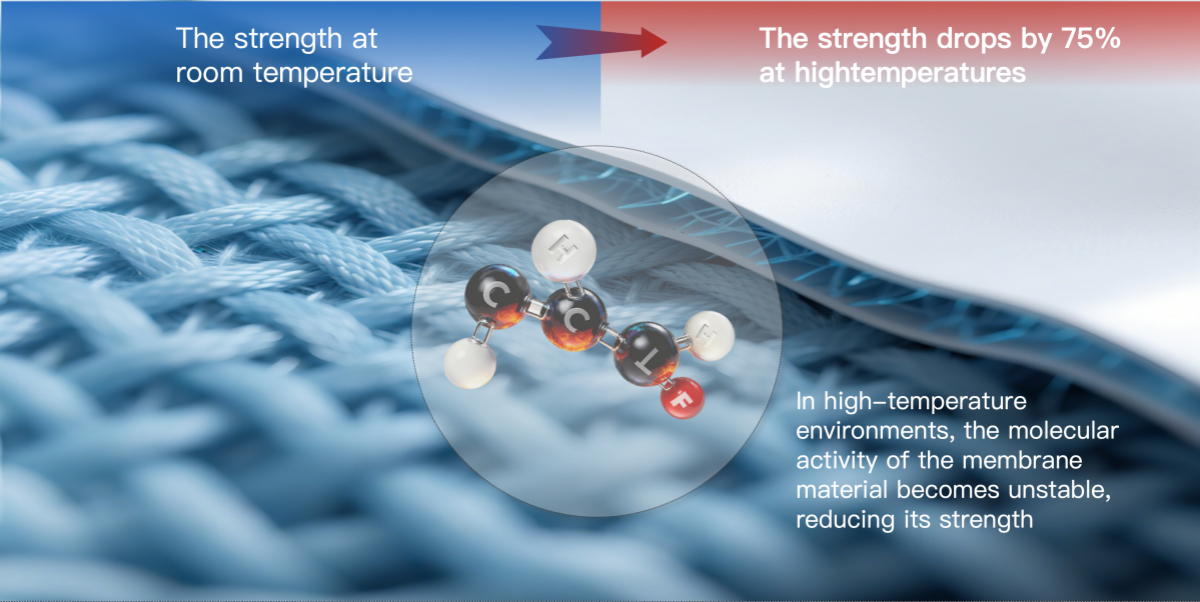

The air dome’s “skin” is PVC (Polyvinyl Chloride). It’s strong at normal temperatures, but at ground temperatures that can hit 60°C, the material undergoes subtle yet dangerous changes.

1. The material softens: At 60°C, the strength of the PVC membrane can drop by up to 75%

PVC is a thermoplastic—it softens when heated. At around 60°C, molecular chain mobility spikes, causing a sharp decline in overall strength. Studies show the membrane’s strength can fall by up to 75% at that point. In short, the structural “skin” becomes far more fragile than expected.

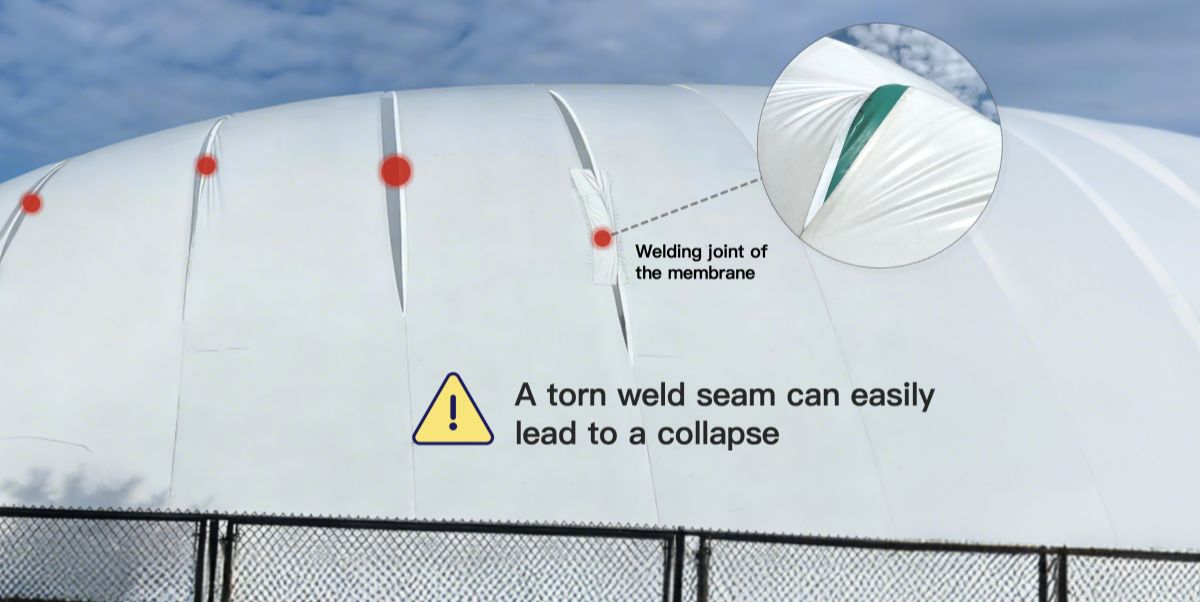

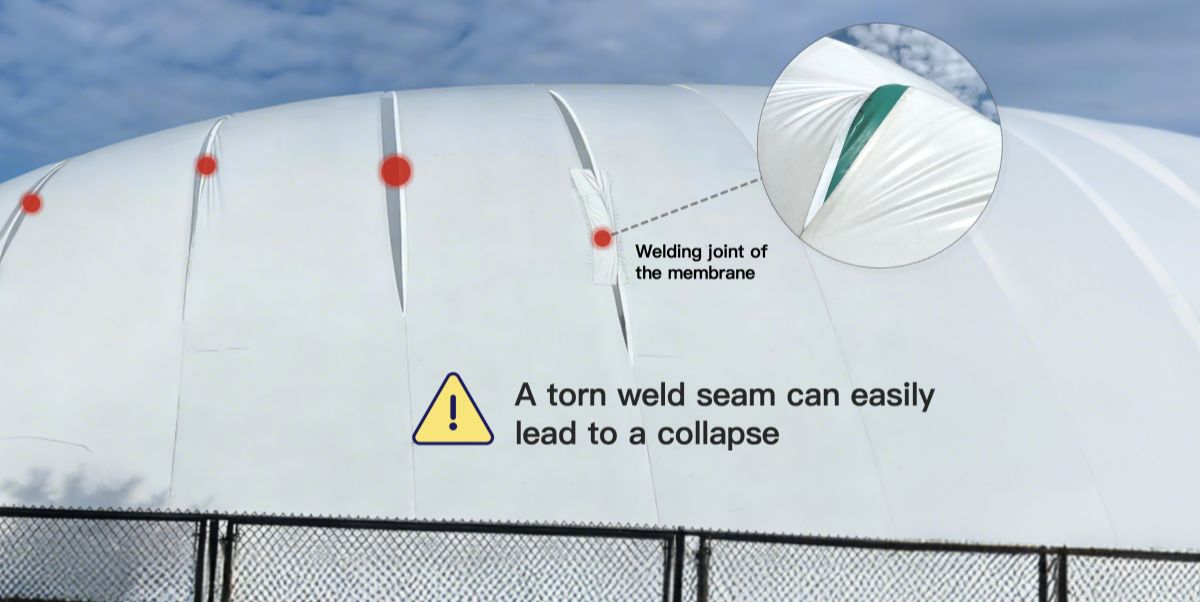

2. Welds become brittle: the weakest link

Air domes are assembled by welding membrane panels; seams are the “stitches.” Welding exposes the seam to a second high-heat cycle, accelerating plasticizer loss (the component that keeps the material flexible) versus surrounding areas. In effect, the seam leaves the factory with some toughness already “spent.” Under extreme heat, it hardens and turns brittle first, making it the most crack-prone part of the structure.

Bottom line: under the Middle Eastern sun, the air dome’s “skin” softens while its “seams” grow brittle.

The Solution: A Diagonal Orthogonal Steel Cable Net System

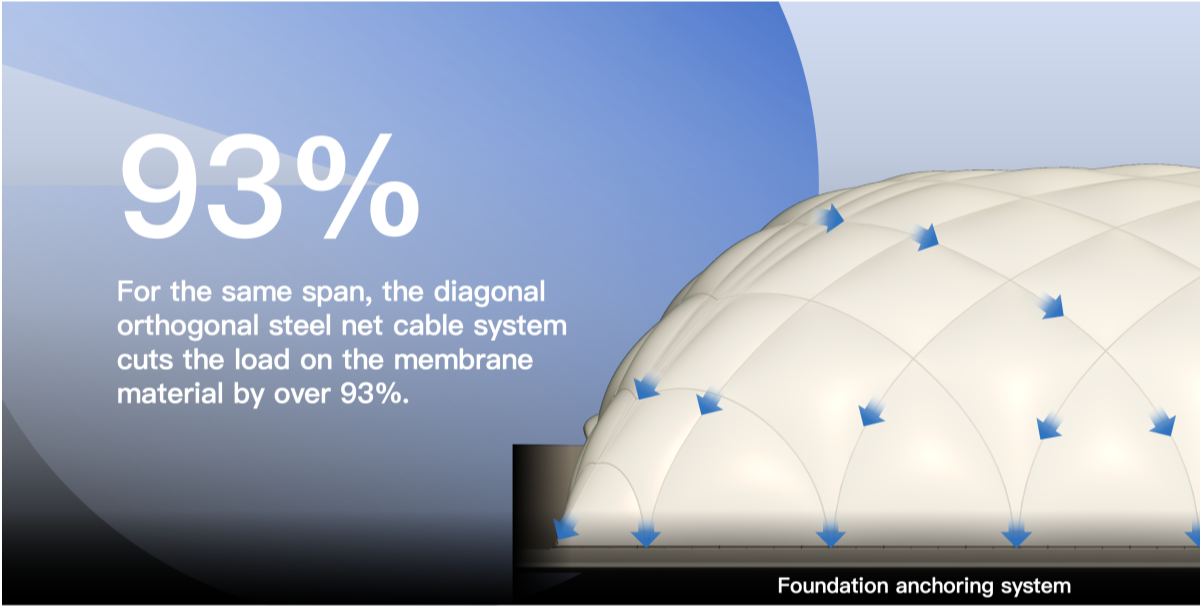

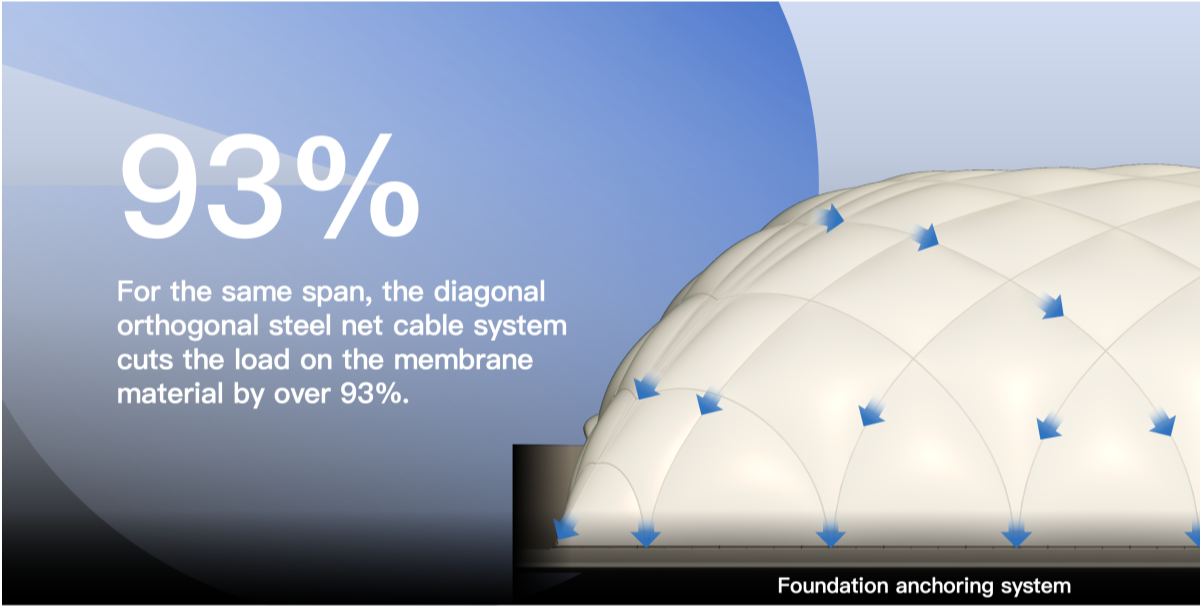

Because the membrane loses strength in high heat, it needs a reliable “skeleton.” This steel cable system forms a crisscrossed mesh over the air dome — essentially a tight, net-like armor.

How it works:

Load sharing: In air domes without steel cables, wind, snow, and other loads are borne by the membrane alone. With the mesh system, most loads — especially wind — are carried by cables whose strength isn’t affected by heat, then transferred directly to the foundation. The membrane shifts from being a primary load bearer to an enclosure, massively reducing its stress.

Deformation control: In sandstorms, a soft membrane can oscillate violently. The mesh cables limit motion, distribute forces, and channel them away, preventing tears — particularly at vulnerable seams — from repeated intense stretching.

Why “Diagonal Orthogonal”?

Only a net-like layout that distributes forces evenly in all directions can handle wind, sand, and loads from every angle without blind spots. Other layouts (simple longitudinal/transverse or cross patterns) can’t form a complete load-transfer network and tend to leave safety gaps, especially at the four corners.

Safety Is Engineered Redundancy

In high-temperature regions like the Middle East — and in hot summer conditions — specifying an air dome with a diagonal orthogonal steel cable net system isn’t an upgrade; it’s a technical necessity.

We recognize the membrane’s performance degradation in extreme heat and counter it with a cable system unaffected by temperature, delivering robust safety redundancy, fail-safe protection for occupants and activities, and shielding clients from the financial risks of safety incidents.