News

Site Editor

Site

/uploads/image/677267645dfcf.png

In the realm of modern architecture and construction, the quest for innovation is unending. One such innovation is the use of air dome technology in building construction. This method employs a thin, durable membrane that is either inflated with air or tensioned to create a structural envelope. The result is a building that is not only aesthetically striking but also offers a range of benefits that are increasingly appealing to architects, builders, and clients alike.

Site

/uploads/image/677267645dfcf.png

In the realm of modern architecture and construction, the quest for innovation is unending. One such innovation is the use of air dome technology in building construction. This method employs a thin, durable membrane that is either inflated with air or tensioned to create a structural envelope. The result is a building that is not only aesthetically striking but also offers a range of benefits that are increasingly appealing to architects, builders, and clients alike.

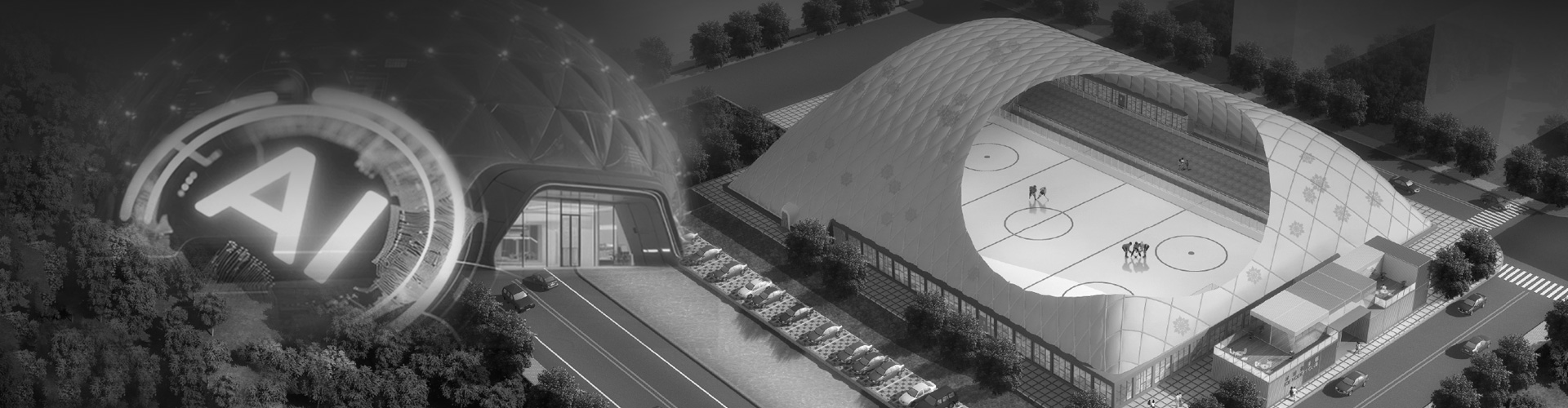

Air Supported Structure : The Future of Construction with Light and Strong Membranes

Views: 3136

Author: Site Editor

Publish Time: 2024-04-25

Origin: Site

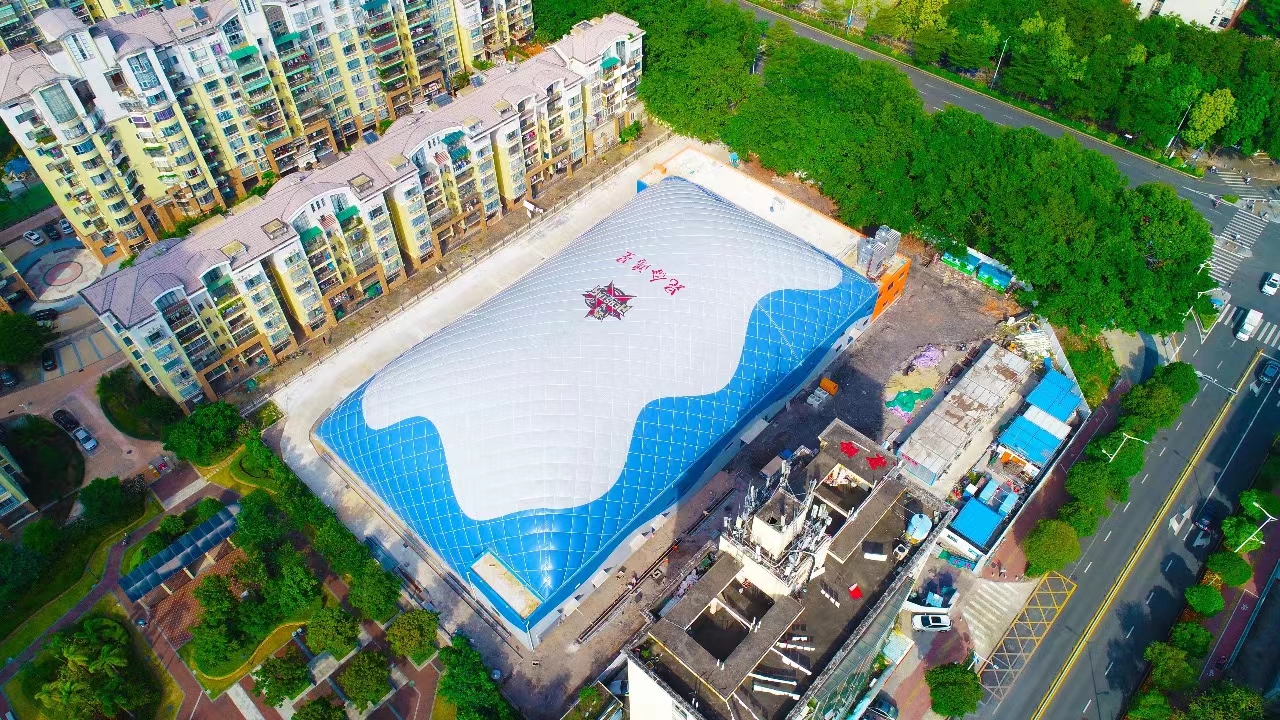

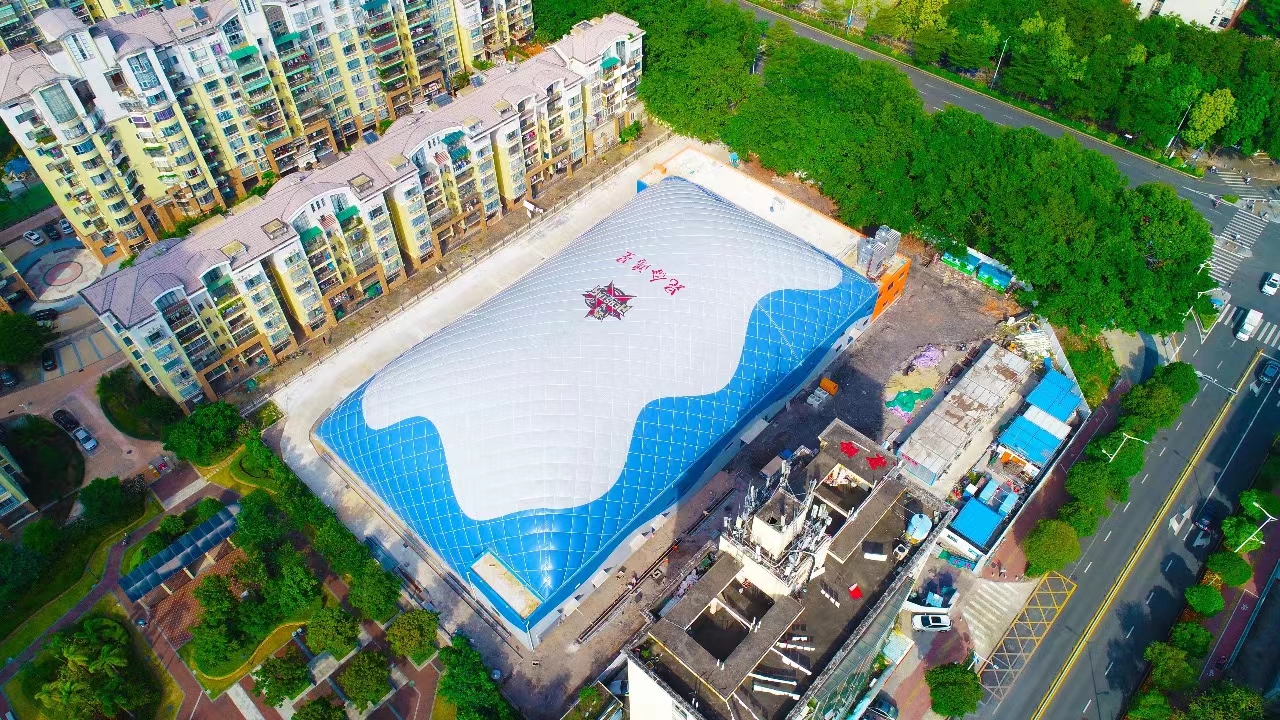

In the realm of modern architecture and construction, the quest for innovation is unending. One such innovation is the use of air dome technology in building construction. This method employs a thin, durable membrane that is either inflated with air or tensioned to create a structural envelope. The result is a building that is not only aesthetically striking but also offers a range of benefits that are increasingly appealing to architects, builders, and clients alike.

Introduction to Air Supported Structure

Air Supported Structure, also known as air dome structures, represent a departure from traditional construction methods. These structures are defined by their use of a single-layered or double-layered membrane that is either filled with air to provide support or tensioned by cables and beams to achieve rigidity.

Key Features of Air Supported Buildings

1. Lightweight and Strong Materials: The membranes used in air supported buildings are typically made from high-strength fabrics such as polyester or polytetrafluoroethylene (PTFE), which are both lightweight and strong. These materials can span large distances without the need for internal supports, creating open, unobstructed spaces.

2. Energy Efficiency: One of the most significant advantages of air supported structures is their energy efficiency. The membranes provide excellent insulation, reducing the need for heating or cooling. Additionally, the reflective nature of some materials can help to keep the interior cool in hot climates.

3. Rapid Construction: Air Supported Structures can be erected much more quickly than traditional structures. This is because the membrane can be installed quickly, and the air inflation process speeds up the construction timeline. This rapid construction can be particularly beneficial for temporary or emergency shelters.

4. Cost-Effectiveness: The materials and processes involved in air film construction are often less expensive than those used in traditional construction. Lower material and labor costs, coupled with the speed of construction, can result in significant savings.

5. Design Flexibility: The flexibility of the membrane allows for a high degree of design creativity. Architects can create complex curves and unique shapes that are difficult to achieve with traditional building materials.

6. Environmental Impact: Air Supported Structure have a lower environmental impact compared to traditional construction methods. The lightweight materials require less energy to transport, and the structures themselves consume less energy to heat and cool.

Applications of Air Supported Structures

Air Supported Structures are versatile and can be used in a wide range of applications:

1. Sports Facilities: Their large, unobstructed interiors make air film buildings ideal for sports facilities, such as gymnasiums and indoor arenas.

2. Temporary Structures: The ease and speed of construction make air supported structure perfect for temporary uses, such as disaster relief shelters, event spaces, or military installations.

3. Greenhouses: The energy efficiency and controlled environment of air supported structures make them excellent choices for greenhouses.

4. Commercial and Retail Spaces: The unique aesthetics and open floor plans of air supported structure can be a draw for commercial and retail spaces, creating a distinctive brand image.

5. Industrial Facilities: For large industrial spaces that require vast, open areas, air supported structures provide a cost-effective and efficient solution.

Challenges and Considerations

While air supported structures offer many benefits, there are also challenges and considerations to keep in mind:

1. Durability and Maintenance: The membranes used in air film buildings can be susceptible to damage from sharp objects, and regular maintenance is required to ensure the integrity of the structure.

2. Weather Conditions: Air-supported structures must be designed to withstand local weather conditions, including wind and snow loads. This requires careful engineering and planning.

3. Fire Safety: The materials used in air supported structure must meet strict fire safety standards, and the design must include appropriate fire detection and suppression systems.

4. Building Codes and Regulations: Different regions have varying building codes and regulations that may affect the design and construction of air supported structures. It's essential to work with local authorities to ensure compliance.

The Future of Air Supported Structures

As the world continues to seek more sustainable and efficient building methods, air supported structures are likely to play an increasingly significant role in the construction industry. With ongoing advancements in materials and engineering, the potential applications for these innovative structures will only continue to grow.